MEP Engineering Design for Kevtrics Pre-Stressed Concrete Factory, Akwa Ibom

MEP Engineering Design for Kevtrics Pre-Stressed Concrete Factory, Akwa Ibom

Project Overview:

TISL was tasked with the MEP Engineering Design for the Kevtrics Pre-Stressed Concrete Factory in Akwa Ibom, a significant project that required a comprehensive approach to meet the industrial demands of a pre-stressed concrete manufacturing facility. This project was completed in 2022 for Income Electrix Ltd.

Strategy and Approach:

The strategy for this project centered on creating a reliable and efficient MEP system that could support the factory’s high-intensity operations. TISL leveraged its extensive experience in industrial engineering to deliver a design that would ensure the facility’s smooth operation while minimizing energy consumption and operational costs.

Design and Implementation:

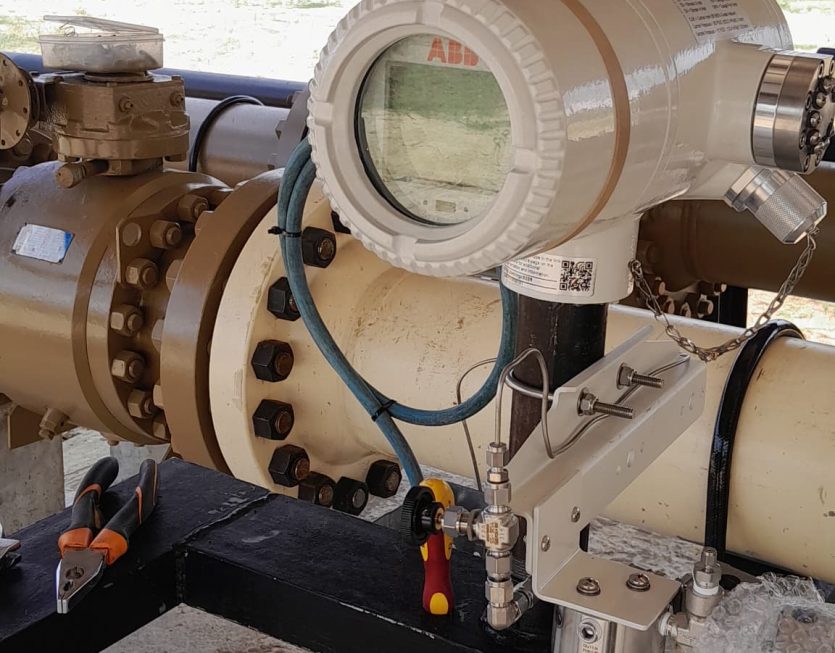

The design included the development of MEP systems for the admin office block, gatehouse, workshop/warehouse, weighbridge, and water and power reticulation. Each element was carefully planned to integrate seamlessly with the factory’s existing infrastructure. The implementation phase involved meticulous attention to detail, with our team ensuring that all systems were installed to the highest standards of quality and reliability.

Client Collaboration:

TISL worked closely with Income Electrix Ltd. throughout the project, ensuring that their specific requirements were met. This collaboration was key to the project’s success, as it allowed us to tailor our solutions to the client’s exact needs. The project was completed on time and within budget, further solidifying TISL’s reputation in the industry.

Environmental Impact:

In keeping with our commitment to sustainability, TISL designed the MEP systems to be as energy-efficient as possible. This not only reduced the factory’s environmental impact but also contributed to lower operational costs, providing long-term value for the client.