Installation and Integration of Gas Chromatograph

Installation and Integration of Gas Chromatograph and Ultrasonic Gas Meter System for Chorus Energy Limited

Project Overview:

Tavak Integrated Services Ltd. (TISL) was engaged by Chorus Energy Limited to undertake the installation and integration of a Gas Chromatograph and Ultrasonic Gas Meter System at their gas processing facility. This project was critical for ensuring precise measurement and analysis of gas composition, which is essential for operational efficiency, safety, and regulatory compliance in the energy sector. Completed in 2023, the project highlighted TISL’s expertise in handling complex instrumentation and automation tasks in the oil and gas industry.

Strategy and Approach:

The strategy for this project was to implement a cutting-edge measurement system that would provide Chorus Energy Limited with accurate and real-time data on gas composition and flow rates. TISL’s approach involved a detailed analysis of the facility’s existing infrastructure, followed by the careful planning and execution of the installation and integration process. The goal was to deliver a system that enhances operational efficiency, supports decision-making, and ensures compliance with industry standards.

Design and Implementation:

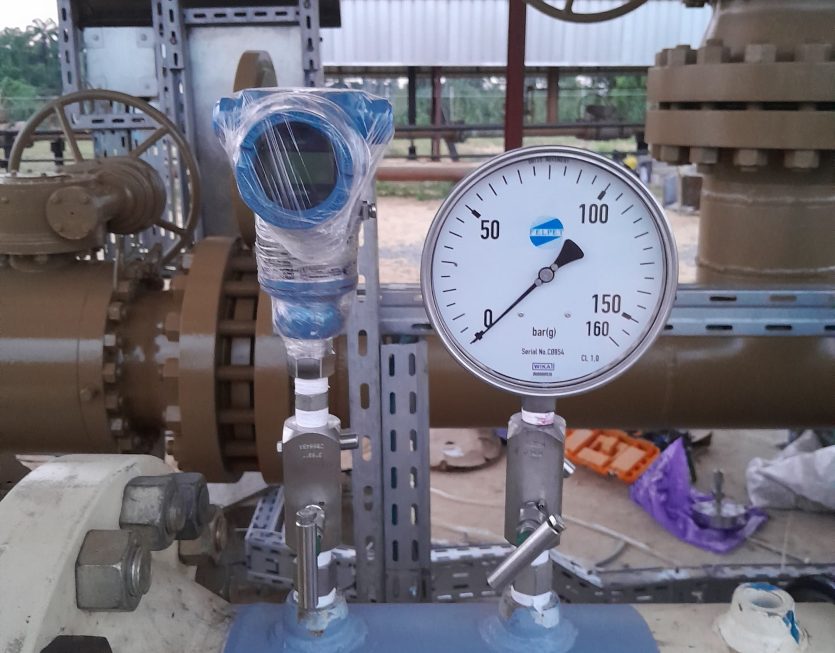

TISL began by conducting a thorough site assessment to determine the optimal placement for the Gas Chromatograph and Ultrasonic Gas Meter. The design phase involved configuring the systems to meet the specific requirements of Chorus Energy’s operations, including calibrating the instruments for accurate measurement and seamless integration with the facility’s existing control systems.

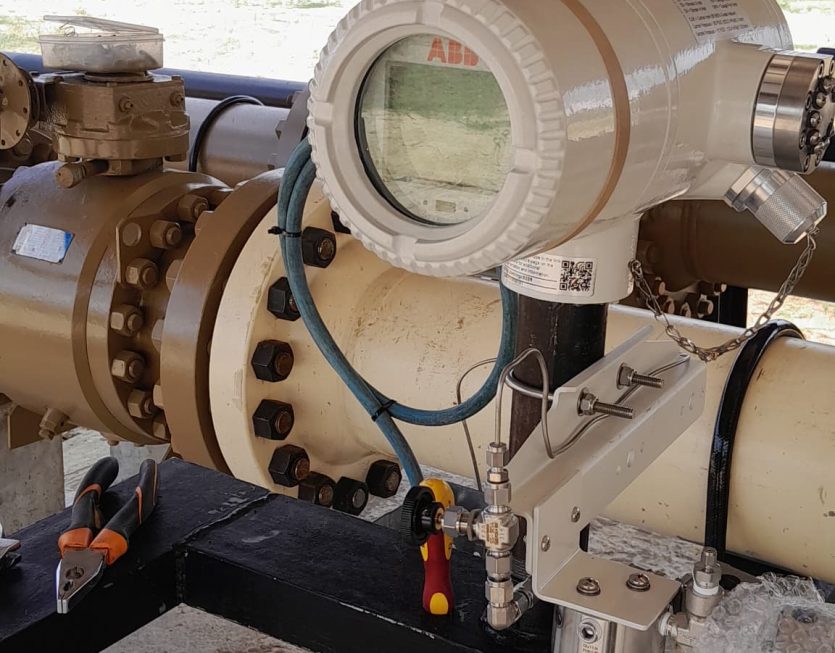

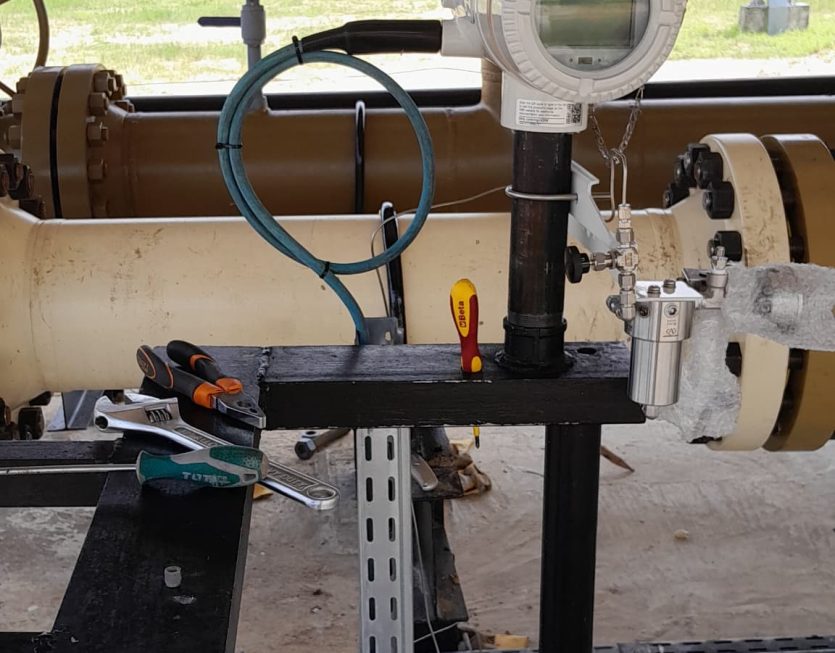

The installation process included the precise placement of the Gas Chromatograph for accurate analysis of gas composition, and the Ultrasonic Gas Meter for measuring gas flow rates with high precision. TISL’s team ensured that all components were installed according to manufacturer specifications and industry best practices. The integration phase involved linking the measurement systems with the facility’s control and data acquisition systems, enabling real-time monitoring and reporting.

Client Collaboration:

Throughout the project, TISL maintained close collaboration with Chorus Energy Limited’s engineering and operations teams. This collaboration was essential to ensure that the installation and integration met the client’s operational needs and regulatory requirements. Regular meetings and site visits were conducted to review progress, address any challenges, and make necessary adjustments. The successful completion of the project was a result of this strong partnership, which ensured that all aspects of the project were delivered on time and to the highest standards.

Environmental Impact:

TISL’s commitment to sustainability was reflected in the choice of technology for this project. The Gas Chromatograph and Ultrasonic Gas Meter were selected for their accuracy and efficiency, which not only improves operational performance but also minimizes environmental impact. By providing precise data on gas composition and flow, these systems help Chorus Energy optimize their processes, reduce emissions, and ensure compliance with environmental regulations. The project demonstrates TISL’s ability to deliver solutions that support both operational excellence and environmental responsibility.