Power Audit for Electrical Systems Installation

Power Audit for Electrical Systems Installation for Pipe Coaters Nigeria Ltd. Facility, Onne, Rivers State

Project Overview:

TISL was engaged by Hat Engineering Ltd. to conduct a comprehensive Power Audit for the Electrical Systems Installation at Pipe Coaters Nigeria Ltd.’s facility in Onne, Rivers State. The project, completed in 2022, involved an extensive evaluation of the facility’s electrical infrastructure, including illumination level checks and a thorough assessment of all electrical installations within the yard. The audit provided valuable insights that informed necessary upgrades and improvements to enhance the facility’s operational efficiency and safety.

Strategy and Approach:

The strategy for this power audit was to conduct a detailed and systematic assessment of the facility’s electrical systems to identify potential issues and areas for improvement. TISL’s approach involved a combination of on-site inspections, testing, and analysis to ensure that all electrical installations were operating efficiently and in compliance with safety regulations. The audit also focused on identifying opportunities for energy savings and reducing the facility’s environmental impact.

Design and Implementation:

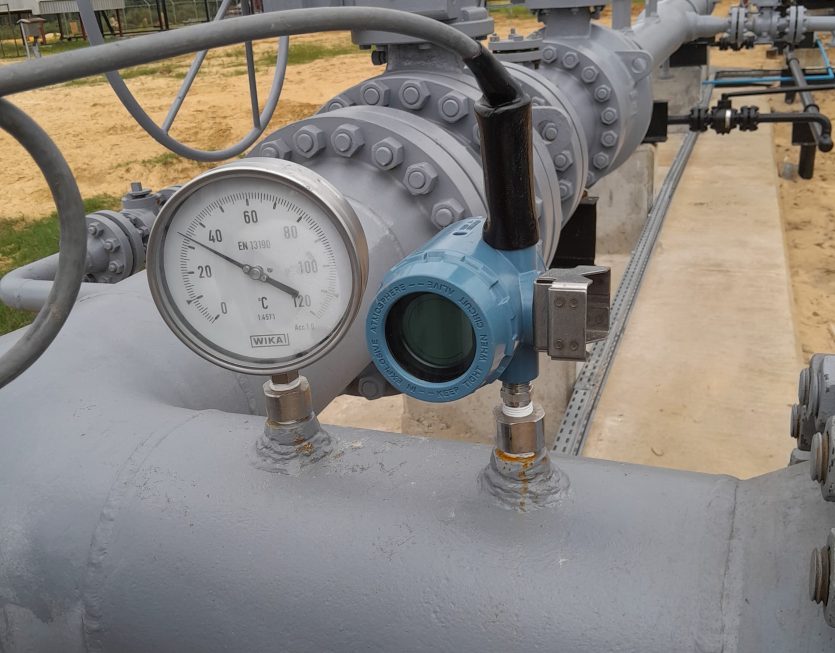

The power audit involved a thorough evaluation of the electrical systems within Pipe Coaters Nigeria Ltd.’s facility. TISL’s team of experts conducted tests to measure illumination levels across the facility, ensuring that lighting was adequate and energy-efficient. The audit also included a detailed assessment of wiring, electrical panels, and other installations, checking for compliance with safety standards and identifying any potential hazards. The findings were compiled into a comprehensive report that included recommendations for improving the facility’s electrical infrastructure, enhancing safety, and reducing energy consumption.

Client Collaboration:

TISL worked closely with Hat Engineering Ltd. and Pipe Coaters Nigeria Ltd. throughout the audit process. This collaboration was crucial in ensuring that the audit was aligned with the facility’s operational needs and that the final recommendations were practical and actionable. Regular meetings and discussions were held to review progress and address any concerns. The successful completion of the audit has strengthened TISL’s relationship with both Hat Engineering Ltd. and Pipe Coaters Nigeria Ltd., showcasing our ability to deliver high-quality engineering services.

Environmental Impact:

As part of TISL’s commitment to sustainability, the power audit included a focus on energy efficiency. The audit identified several areas where energy consumption could be reduced, leading to recommendations for upgrading lighting systems, optimizing power usage, and reducing waste. These recommendations not only help reduce the facility’s environmental impact but also contribute to cost savings for Pipe Coaters Nigeria Ltd.